3 high-impact ways the industrial sector can become more sustainable

Did you know that the industrial sector is responsible for approximately 21% of all carbon emissions worldwide? According to a report by Global Carbon Project, industrial activities and burning of fossil fuels blasted an estimated 36.8 billion metric tons of carbon emissions into the atmosphere in 2019 out of a total 43.1 billion metric tons that human activities stand for.

Clearly, this makes mitigation of the most aggressive consequences of rising global temperature, which is caused by carbon emissions, an issue that needs to be addressed by the industrial sector.

What mindset and action can this sector take to reduce its carbon footprint?

We've listed sustainable changes that can be made in order for industries to close the gap between their current carbon emissions and the trajectory it needs to be on.

1. Resource-efficient machinery to reduce carbon emissions and increase value

Since consumers are more interested in buying sustainable products than ever before, businesses need to meet that demand by rethinking the impact of their entire supply chain. The industrial sector is often a second or third tier in the supply chain, and is thereby impacted by the pressure to work sustainably. In order to stay relevant and be chosen in a business supply chain, the machinery used to produce products in the industrial sector need to be smarter and better customized to minimize the unnecessary use of resources.

For example, according to the UN Global Impact, companies in the industrial sector that prioritize building agribusiness machinery that helps facilitate precise agriculture, reduce water intensity, soil compaction, and energy consumption will – and already do – create shared value. This kind of technology is at the brink of a boom and companies within the industrial sector that adopt this kind of technology early on will benefit from becoming a market leader at the forefront of driving innovation forward. Not least, they are most likely to win over mature sustainable businesses – an area growing in size and number – as their manufacturer of choice.

Resource-efficient with low carbon-emission machinery is not only limited to agribusiness but also includes products that are used every day by consumers, particularly in the transportation sector. This means producing more sustainable vehicles – from planes to ships to buses, trains, and trams. The carbon emissions of these products, used constantly and globally, is a significant contributor to climate change. Businesses that invest in climate friendly technologies are positioned to become world-leading companies, and thus choose manufactures that do the same. An easy example of this is Tesla, an electric vehicle and clean energy company, which made an annual revenue of $31.536B, a 28.31% increase from 2019. In January 2020, Tesla became the America’s most valuable auto company American history was written. Why? Consumers drive the market, and they want to drive cars that create less impact on the planet.

2. Circular economy & industry 4.0

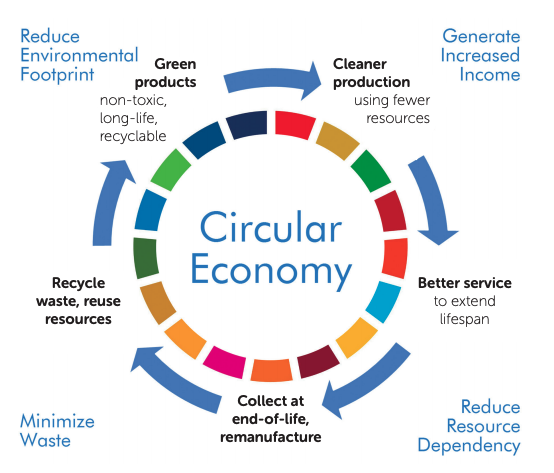

According to Accenture, 83% of consumers believe it’s important or extremely important for companies to design products that are meant to be reused or recycled. The United Nations Industrial Development Organization (UNIDO) describes the circular economy as products “designed for durability, reuse and recycability, and materials for new products come from old products.” In essence, it is the opposite of, and revolution against, the throw-away economy. By creating reusable products, industries contribute to a reduced environmental footprint, generate increased income, reduce resource dependency, and ultimately minimize waste.

The circular economy. Source: UNIDO

However, in order for the circular economy to become a reality, businesses must adapt to, and create, innovative business and partnerships with this new thinking in mind and integrate the next generation of industry technology: Industry 4.0.

Industry 4.0 refers to the computerization of manufacturing and using a range of new technologies that combine the physical, digital, and biological worlds. According to Professor Klaus Schwab, this revolution will impact all economies and industries and has the potential to “drastically improve the efficiency of business and organizations and help regenerate the natural environment through better asset management, potentially even undoing all the damage previous industrial revolutions have caused.”

Concretely, this means there will be a shift from centralized to decentralized, autonomous and intelligent manufacturing and production. Solutions including the Internet of Things (IoT), cloud computing, and 3D printing will help do so. According to UNIDO, these technologies create flexible industrial processes, interoperability, and contributes to better cross-collaboration between departments, partners, and vendors. Essentially, these technologies have the capacity to create a more efficient and sustainable supply chain.

Bernard Marr & Co, a world-leading independent think tank, argue that business leaders who want to thrive in the future economy need to break free from what has traditionally worked in the past and expand their mindset to include never-before considered ideas, systems, and technologies, and let them inform core business models to lead the way.

More than half of consumers admit that they would pay more for sustainable products that are designed to be used or recycled – that is, designed with a circular economy in mind. Industrial businesses that build their core business model around this mindset win over vendors and consumers ready to pay for sustainable products.

3. Decrease the amount of fossil fuels

Fossil fuels contribute significantly to carbon emissions, and negatively impact the short-term and long-term health of our planet and its people. However, it is still the dominant source of energy worldwide. The problem – and opportunity – is that only a few dozen companies can be traced back to and are responsible for more than one-third of all greenhouse gas emissions, caused by fossil fuels. If these few dozen companies – and the industrial sector as a whole – integrate sustainability as part of their core business, they have the potential to reduce climate degradation for the world’s population. Furthermore, by drawing upon innovative technologies, these companies can become a market leader in renewable energy or other long-lasting and positive impact business models. As Michael Mann, a leading climate scientist, puts it:

“The great tragedy of the climate crisis is that seven and a half billion people must pay the price – in the form of a degraded planet – so that a couple of dozen polluting interests can continue to make record profits. It is a great moral failing of our political system that we have allowed this to happen.” – Michael Mann

By increasing the amount of energy used from renewable sources such as wind, solar, and biomass, the amount of fossil fuels burned will decrease and less heat will be trapped in Earth’s atmosphere. As vendors adjust to the conscious consumer, businesses are beginning to pick industrial partners based on their sustainability and transparency in order to clean up their own supply chains. Thus, there is a financial incentive and growth opportunity for corporations that work with renewable energy and decrease the amount of carbon emissions.

Adopting resource-efficient machinery, implementing a circular economy mindset with Industry 4.0 technologies, and reducing the amount of fossil fuels burned are three high-impact ways the industrial sector can respond to increased expectations, and tangibly contribute to a more sustainable world.

Learn more about calculating and measuring your organization's own environmental footprint in our popular on-demand webinar!

Related blog posts you might like:

%20as%20the%20deadline%20approaches.%20Learn%20about%20compliance%20requirements%2c%20potential%20delays%2c%20and%20key%20updates..png)