Why everyone’s focusing on supply chain transparency and what it means

Any chain is only as strong as its weakest link, and the same is true for supply lines which keep the majority of businesses thriving during day-to-day operations. Supply chain transparency is a similar concept, as companies are now realizing their need to take responsibility for the sustainable operations in tiers further down the line. Consider Apple, and the flak they get for conditions suffered by factory workers who make iPhones in China (that’s without getting into the various raw materials that go into producing their devices, sourced from all over the globe.). A better understanding of supply chain transparency will help businesses avoid risks and digital solutions help make it a painless process.

The different stages of supply chain transparency

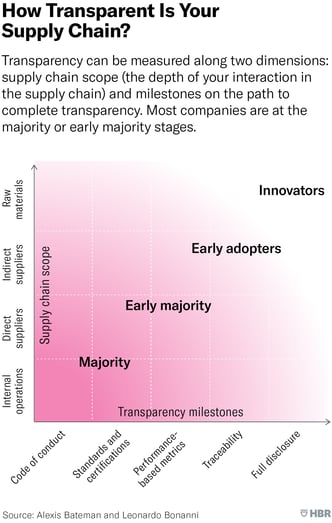

No two companies will have the same business requirements, and the same is true in terms of their supply chain transparency. However, you can measure the impact of transparency along supply chains via a simple two-dimensional axis. The scope considers how deeply you interact with different stages of the supply chain, while milestones show how far you’ve come along the way.

The scope begins with internal operations, leading on to dealings with direct suppliers, then sub-suppliers, and finally the raw materials themselves. It’s a clear, logical progression through the supply chain, and each tier requires more time, manpower, and resources. After all, internal ops may involve sending a memo or having a meeting about new procedures, but ensuring raw materials are ethically sourced along a supply chain will definitely take additional effort.

On the second line of the axis, businesses that want to gain transparency need to achieve milestones that start with a code of conduct, moving on to ensuring you have the correct standards and certifications. Performance-based metrics are next on this list, leading on to traceability, and finally full disclosure.

The milestones allow for companies to track and trace their progress along their journey to being truly transparent, which is clearly a growing concern in terms of compliance.

Finally, companies will be placed somewhere on the graph, depending on the steps they’ve already taken to attain transparency. In chronological order they are; majority, early majority, early adopters, and innovators.

For example, if you only have a code of conduct for internal operations, you’d be in the majority, along with most other companies. If you offer full disclosure for the sourcing of raw materials, you’re an innovator when it comes to transparency. Companies should aim to take a couple of steps forward, as most are stuck at the ‘majority’ stage on the graph.

How to gain transparency through digital solutions

1. Setting goals and understanding associated risks

One way to improve supply chain transparency is to set clear aims, but to do so you’ll need to factor in the accompanying risks. As well as materiality assessments, this can also involve checking future regulations, or taking the time to understand any issues the company has faced in the past.

The point is, a deeper and broader understanding of risks should help a company achieve their stated aims regarding transparency. On the other hand, there’s no point in attempting to identify risks without setting aims and goals, and having an action plan to manage problems that may arise.

2. Visualizing your supply chain

With the information you’ve previously gathered in terms of perceived risks and the stated goals, it should now be easier to visualize the target supply chain, as well as filling any gaps.

You’ll have to map out the supply chain, but this ‘visualization’ will allow for a deeper understanding of the suppliers involved, and the associated risks. The data you collect at this stage should align with the goals decided on in the first step.

3. Actionable information

This documentary lays out the hard facts on fast fashion and its, in many cases, unsustainable supply chain. While exploring several areas of the garments lifecycle, from production and life of low wage workers in developing countries, to after-effects such as river and soil pollution, pesticide contamination and severe diseases. The True Cost pulls back the curtain on the untold story and asks us to consider, who really pays the price for our clothing?

4.Engaging and disclosure

With a heap of new information about your supply lines, procedures, and practices, you’ll now have the opportunity to decide what to do with it. Of course, you’ll want actionable insights, since you’ll probably need to engage with the suppliers to address any risks found along the way.

The type of engagement is up to you, and the same goes for disclosure. Deciding on the level of disclosure can be difficult, and, as mentioned, this ranges widely dependent on factors such as industry, company size, and the complexity of a supply chain.

For example, a revised code of conduct would be an indication of new practices and increased transparency, while releasing information about your dealings with indirect suppliers would be further along in terms of scope and milestones.

There’s no right or wrong answer, but digital tools should go some way to help you to bridge any gaps and achieve full transparency.

Other blog posts you might like:

%20as%20the%20deadline%20approaches.%20Learn%20about%20compliance%20requirements%2c%20potential%20delays%2c%20and%20key%20updates..png)